The laminator worked like a charm.

Closing the laminator worked even better !!!

After passing 20 times the copper clad at "80 mic" i could do toner transfer to the copper really easily with consistent results.

I am pretty sure that the 170 OC isn't reached at all thats why i have to pass the copper clad that many times but i prefer to keep it right now like this.

So i hacked the United Office ULG 300 A3 laminator virtually without anything !

I just switched the positions of the two thermostats and i placed a 1.6 mm copper clad single side fr4 22mm*22mm piece underneath the 160 OC thermostat !!!

Of course it is always better to change the 160 OC thermostat with a 170 OC.

Now it is time for some cosmetics.

Since the copper is rigid i needed to add two wooden front legs at the laminator made by toothpicks

😀

The two toothipick legs were added at the front two screw holes and then cut at the right length.

Below is the final result

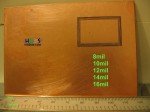

Here are some results done with this laminator

The KiCad PCB test in order to test your own laminator can be downloaded by clicking at the Kicad Test

A demonstration video

Enjoy !