We talk again of Serialino, our Arduino's clone: this time the printed circuit board (PCB) design is shown.

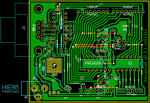

Here beside you find a screen-shot of the PCB of Serialino, numbered 1.0.

Even from here you should be able to distinguish the areas described in the previous post.

Power supply section on the bottom-left; the communication port and IC Max232 on the top-left; the headers on top and bottom; and finally ATMega with external oscillator, then the switch button and the ICSP pin headers.